Marine aquaculture floating bucket series products

Key words:

Classification:

Marine oyster row culture series products

Product accessories:

Marine aquaculture floating bucket series products

Graphic Details

Components of Oyster Row

The buoyancy and bearing system of the oyster row are closely connected, the installation is convenient, the structure is stable, and it has better wind and wave resistance.

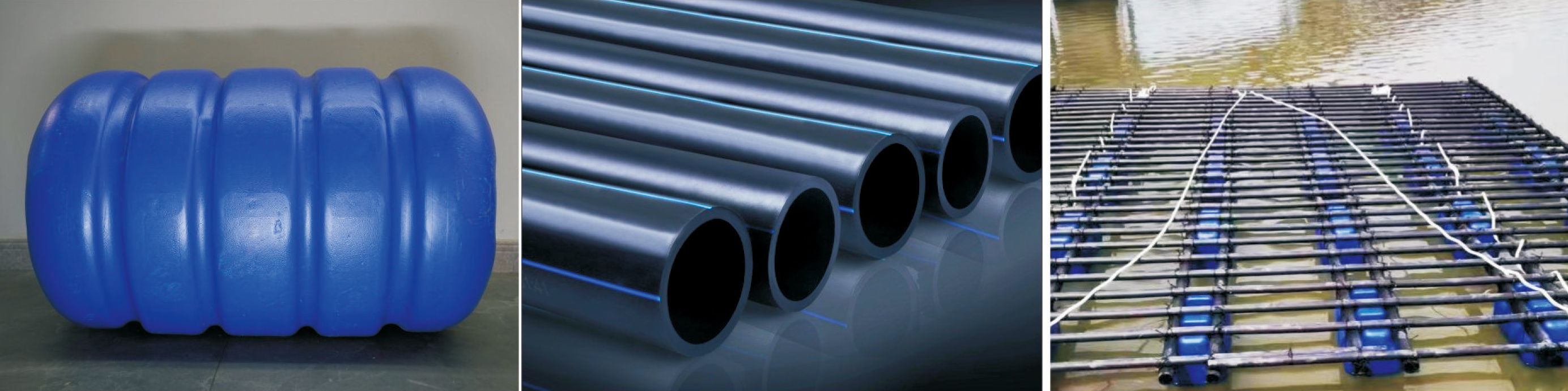

streamlined body wave-eliminating buoyancy system

Float using hollow blow molding processing, heavyThe light weight is large, the salt and alkali corrosion resistance, the simple body adopts the streamline body design and adds the wave-like current wave elimination groove,

The flow rate of water is reduced, the overall impact on the buoy is weakened, and the structural compressive strength of the buoy is further improved.

Oyster Steak Assembly

Main pipeline laying

1.1 At the construction site, both ends of the load-bearing pipe DN125 are welded and sealed with plugs to form a closed cavity to increase buoyancy and prevent sinking into sea water. Hot melt butt welding machine can be used.

1.2 Lay the horizontal load-bearing pipes first, arrange the buoys in a straight line as required, and place the buoys at a distance as required. Take two DN125 pipes and place them on both sides of the buoys. The distance is the fixed size during the design of the buoys. Two people are required to cooperate to place the DN125 pipes on the left and right sides of the buoys respectively, and then bind them with a rope of 5mmPE diameter; bundling is performed in order from left to right. Bundling the required pontoons.

2. Lay longitudinal load-bearing pipes again. Take DN75 pipes and lay them on top of DN125 pipes. The spacing shall be determined according to the design requirements. Generally, they shall be bundled from one side to the other first, and all DN75 pipes shall be bundled.

3. Finally, all DN125 and DN75 pipes are bound for the second time. The direction of the binding rope is 90 degrees from the direction of the first binding rope, and the second binding rope is bound into a dead joint to prevent the pipes from shifting and loosening during use.

4. After the completion of the acceptance steps, check whether the binding is firm, bearing pipe spacing is in line with the design requirements, pipe and buoy is damaged.

5. Oyster row transfer, acceptance of qualified oyster row need to use machinery for consignment or hoisting, in the process of transfer to gently, to avoid pipe and buoy damage.

6. After being transported to the destination, the oyster rows should be anchored. The front, back, left and right anchoring should be carried out. The oyster rows that need to be combined need to be fastened to each other.

7. After the inspection of the anchored oyster rows is completed, the oyster seedlings can be loaded. After the number of oyster seedlings is filled as planned, the bearing capacity and draft depth of the oyster rows can be checked. Regularly inspect the load-bearing situation of oysters, and timely replace and tighten deformation and looseness.

Environmental protection, corrosion resistance, recyclable

Using high density and high toughness HDPE material, green environmental protection, and has strong corrosion resistance, can be recycled.

Previous

Marine aquaculture floating bucket series products/floating bucket

Product consultation

Product Consulting

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will get in touch with you as soon as possible.

National customer service telephone

Site Map

WeChat Public Number