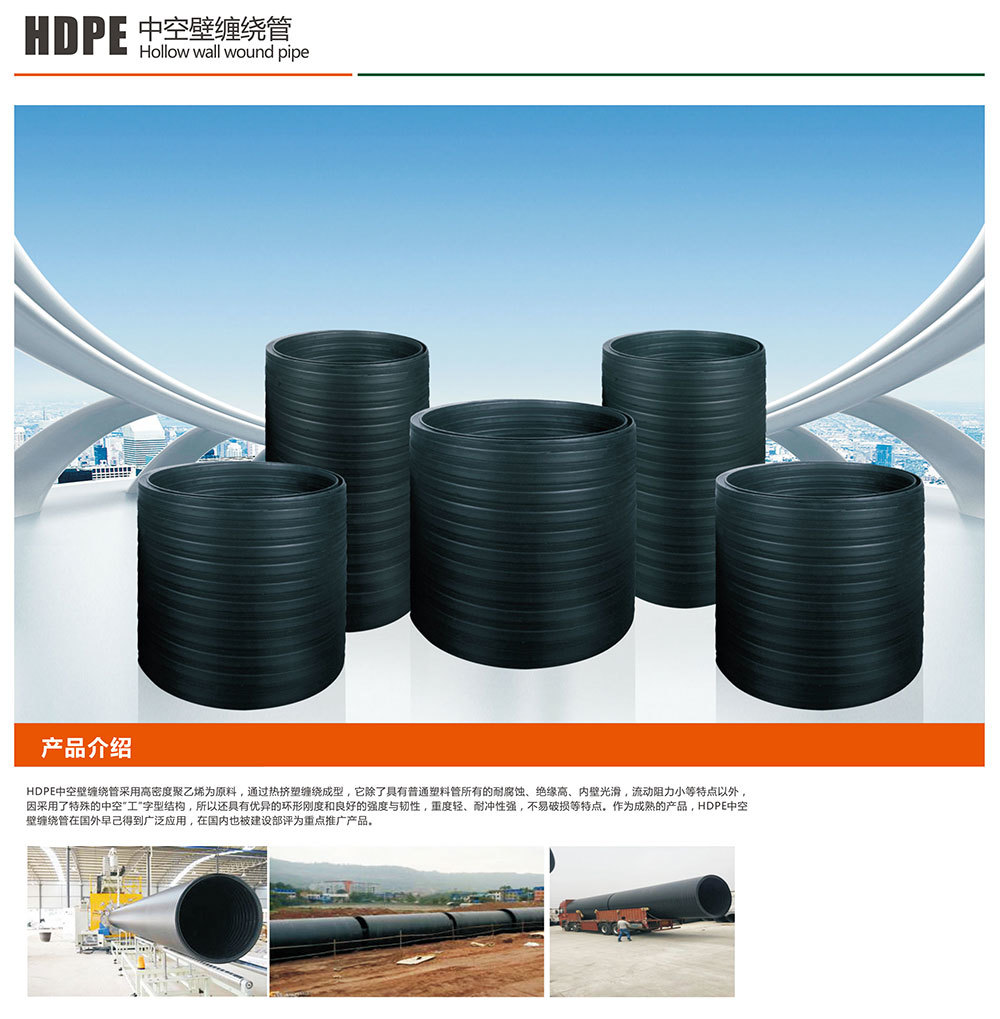

HDPE hollow wall winding pipe

HDPE hollow wall winding pipe is made of 100 high density polyethylene (HDPE) as the material, using a special extrusion process in the hot melt state winding molding, while welding into the whole made of pipe. In order to meet the physical mechanics and other performance requirements of a certain standard, in accordance with the optimization design of the pipe wall, the use of winding molding process made of various rib-type structure wall pipe collectively. Including polyethylene wound double wall rectangular hollow rib wall pipe and polyethylene wound.

Key words:

Classification:

Hollow wall winding pipe

Product accessories:

HDPE hollow wall winding pipe

Graphic Details

HDPE hollow wall winding pipe is made of 100 high density polyethylene (HDPE) as the material, using a special extrusion process in the hot melt state winding molding, while welding into the whole made of pipe. In order to meet the physical mechanics and other performance requirements of a certain standard, in accordance with the optimization design of the pipe wall, the use of winding molding process made of various rib-type structure wall pipe collectively. Including polyethylene wound double wall rectangular hollow rib wall pipe and polyethylene wound.

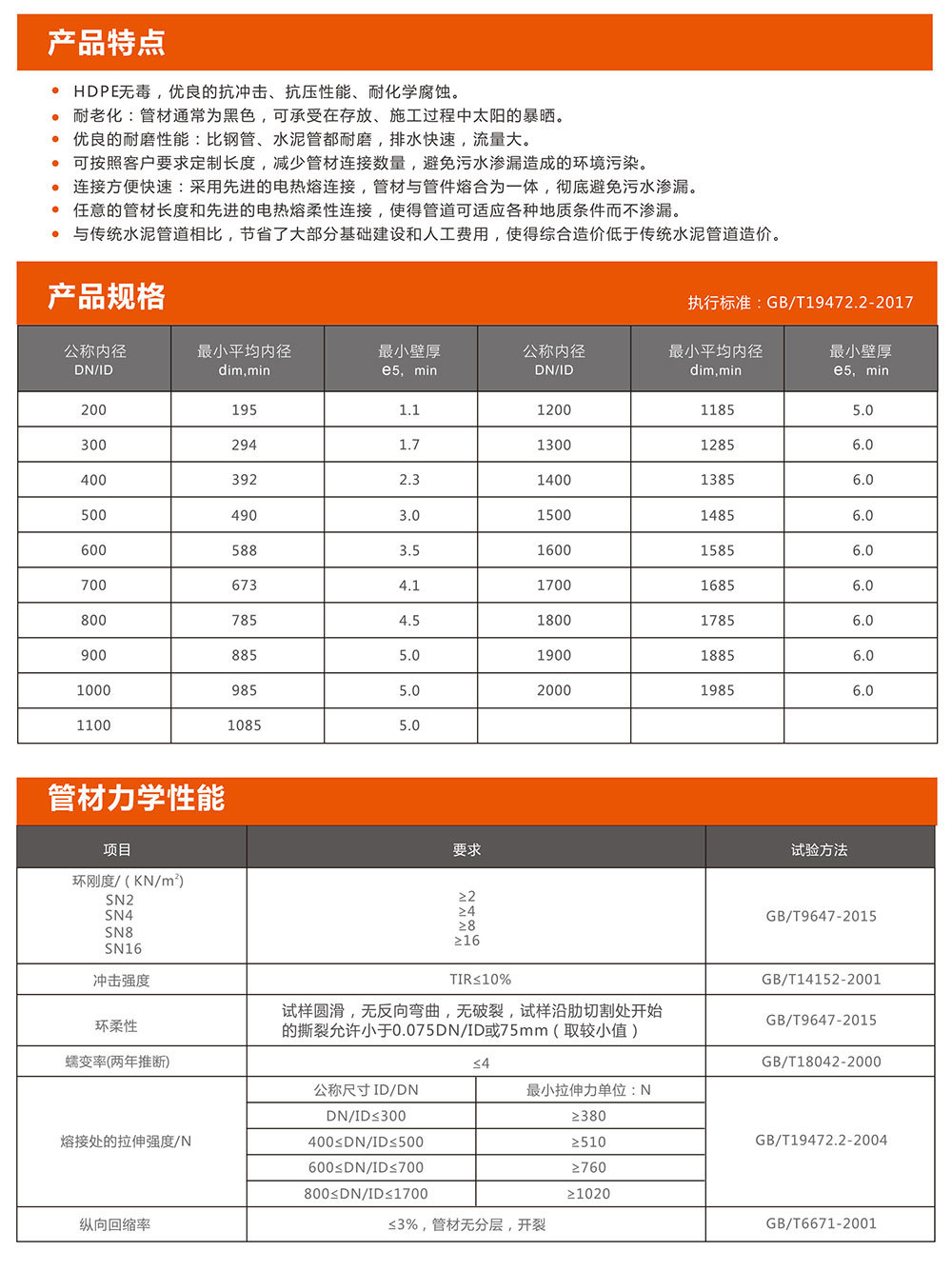

HDPE hollow wall winding pipe with high density polyethylene as raw material, through the hot extrusion winding molding, the product uses a special extrusion process in the hot molten state winding molding, while welding into the whole made of pipe. Its inner wall is smooth and flat, and the specification is DN200- DN2600mm.

HDPE hollow wall winding pipe with high density polyethylene as raw material, through hot extrusion winding molding, the product production process is reliable, wide range of production, product performance is stable, is the rapid development of buried drainage pipe, is accepted by the market and widely used.

HDPE hollow wall winding pipe has a flat inner and outer surface, and the pipe connected by square spiral ribs between the inner and outer walls is a flexible pipe, which has good extensibility, strong compression resistance and uneven settlement ability, and improves the earthquake resistance and disaster reduction ability of public facilities.

The pipe wall adopts a special hollow "I" type structure, which has excellent ring rigidity and good strength, reduces the weight of the pipe, and improves the comprehensive mechanical properties of the pipe.

So you will certainly ask it and the double-wall corrugated pipe looks so much like, what is the difference between them.

Differences in process and performance

The production cost of the two pipes is different when the diameter and ring stiffness are the same.

Differences in connection.

Previous

None

Next

Product consultation

Product Consulting

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will get in touch with you as soon as possible.

National customer service telephone

Site Map

WeChat Public Number