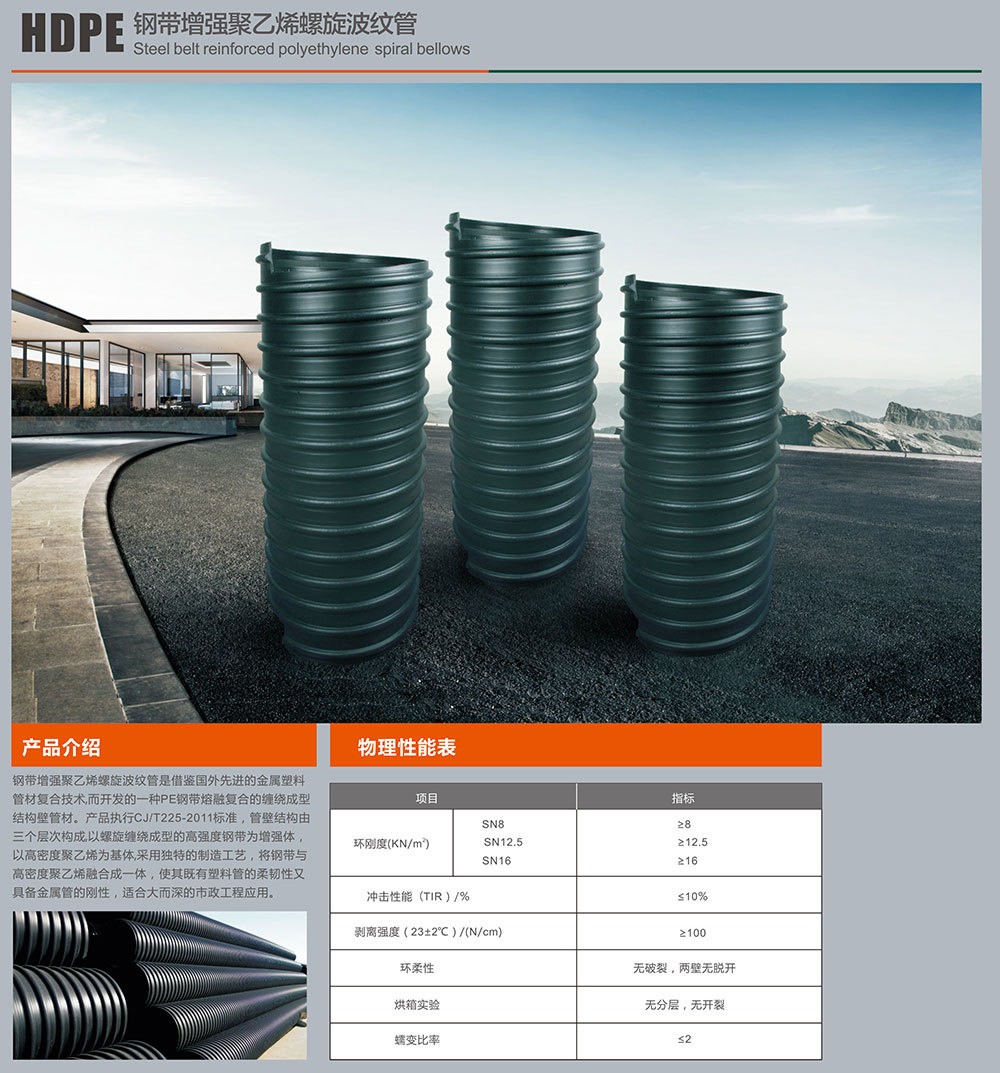

HDPE steel strip reinforced polyethylene spiral corrugated pipe

HDPE steel belt reinforced spiral corrugated pipe adopts U-shaped steel belt composite PE material, which greatly improves the ring stiffness of the pipe without increasing the cost, and greatly improves the strength of winding pipe and carat pipe under the same weight. It can solve a series of problems such as heavy load, and the advantages of large-diameter pipes are more obvious. The diameter of the production pipes ranges from DN300mm to DN2400mm, and the ring stiffness is kept above 8KN/m2, which is lighter and stronger than cement pipes and other plastic pipes.

Key words:

Classification:

Steel belt reinforced PE spiral corrugated pipe

Product accessories:

HDPE steel strip reinforced polyethylene spiral corrugated pipe

Graphic Details

HDPE steel belt reinforced spiral corrugated pipe adopts U-shaped steel belt composite PE material, which greatly improves the ring stiffness of the pipe without increasing the cost, and greatly improves the strength of winding pipe and carat pipe under the same weight. It can solve a series of problems such as heavy load, and the advantages of large-diameter pipes are more obvious. The diameter of the production pipes ranges from DN300mm to DN2400mm, and the ring stiffness is kept above 8KN/m2, which is lighter and stronger than cement pipes and other plastic pipes.

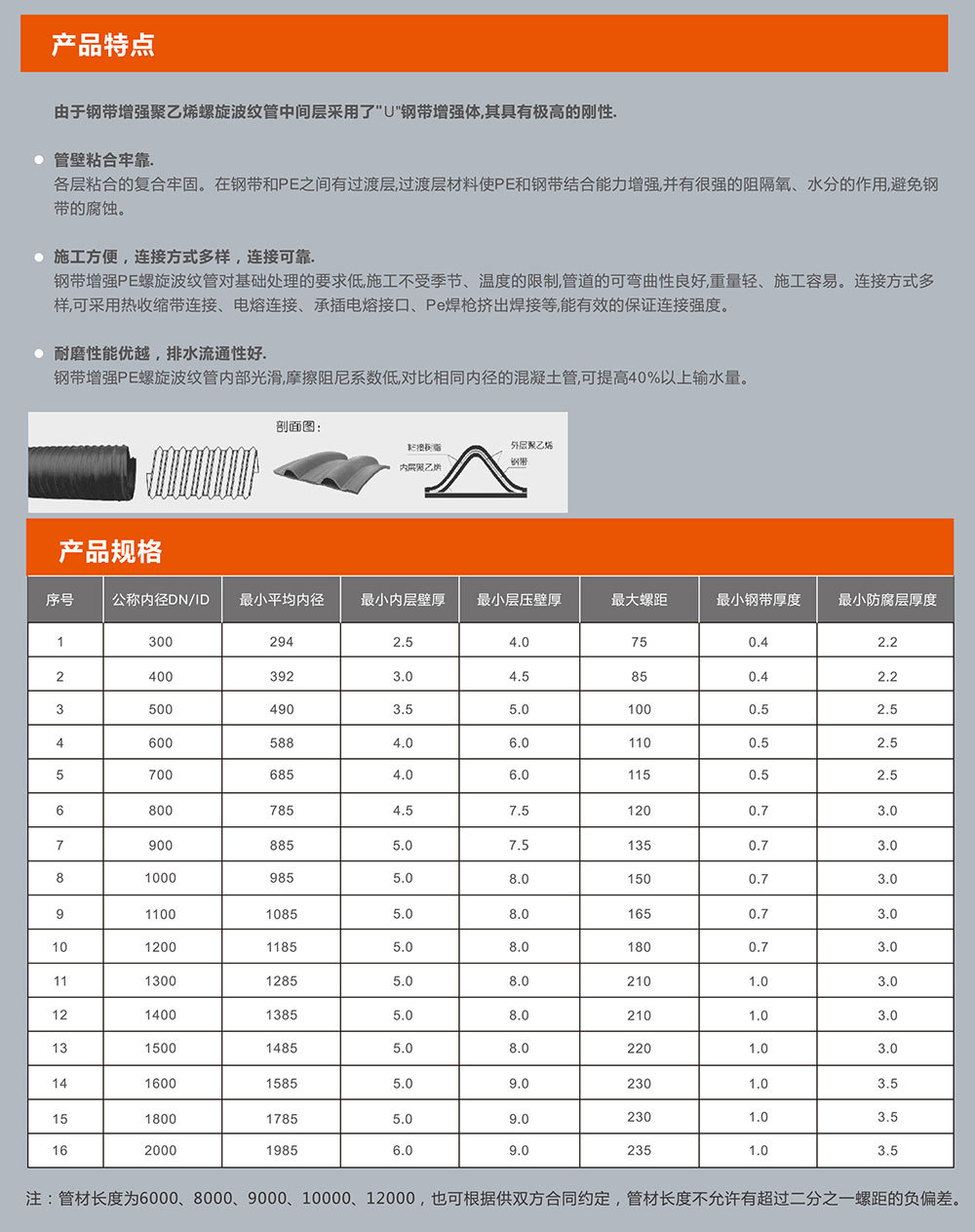

The compounding of each layer is carried out in the molten state of the plastic; it is completely different from the secondary melting molding of the winding tube (hollow wall tube), so the layers are completely bonded and the fastness is very high.

The surface of the steel strip is specially pretreated to enhance the anti-corrosion ability of the steel and the adhesion between the steel and the plastic, and improve the peel strength. In the plastic raw material fully molten state winding molding, the overall structure of the pipe is firm and reliable. Due to the use of special materials and processes to solve the problem of steel plate corrosion and steel plate and PE material adhesion, so that the service life of the pipeline and pure plastic pipe, guaranteed in more than 50 years.

HDPE steel reinforced spiral corrugated pipe can be used by electric hot melt connection, heat shrink tape connection, internal and external extrusion welding or a variety of connection combination, the connection is firm. Reliable connection can make the pipeline reach zero leakage.

Characteristics of HDPE steel strip reinforced spiral corrugated pipe

1, chemical resistance: no pollution, waste water and chemical corrosion, not due to soil decay material and corrosion;

2. Impact resistance: the pipe wall adopts "U" shaped structure, which is impact resistant and pressure resistant, and does not crack under the condition of foundation sinking, and has strong recovery after deformation, and has good adaptability to the foundation;

3, aging resistance: the pipe is usually black, can withstand the storage and construction process of the sun;

4, cold resistance: the pipe will not be frozen crack and expansion of water leakage in -60 ℃ environment;

5, light weight: easy to transport, convenient construction, is the weight of cement pipe 1/8, buried pipe only need excavator, do not need large equipment.

Previous

None

Next

Product consultation

Product Consulting

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will get in touch with you as soon as possible.

National customer service telephone

Site Map

WeChat Public Number